High Quality DOUBLE SIDE GREY CHIPBOARD PAPER, GREY CARDBOARD, Duplex Board, Dulpex Paper Board, Coated Duplex Board With Grey Back, Duplex Board with Grey Back

High Quality DOUBLE SIDE GREY CHIPBOARD PAPER, GREY CARDBOARD, Duplex Board, Dulpex Paper Board, Coated Duplex Board With Grey Back, Duplex Board with Grey Back

Product Description

grey chip board or grey board, divided into two categories, one is made of waste cardboard, paper skin, and wood chips as the core. This kind of cardboard belongs to low-grade double-grey cardboard. The other type is made of waste newspaper pulp, which is smooth and flat.

Double gray cardboard is mainly used to make hardcover books, notebooks, recipes, photo frame backboards, folders, pads, partitions, advertising boards, luggage, all kinds of liners, desk calendars, all kinds of paper boxes (gift boxes, cosmetic boxes) , storage boxes, high-end wine boxes, tea boxes, food packaging boxes, high-end clothing boxes, thermal underwear boxes, high-end shirt boxes, tie boxes, shoe boxes, export sheets and quilt boxes, etc.) shopping bags and non-square cloth household items, etc.

Gram weight: 250G, 300G, 350G, 450G, 650G, 750G, 800G, 850G, 900G, 1000G, 1200G, 1500G, 1800G, 2000G, etc. 250g-5000g

Product Specifications

Flat: International standard size: positive degree 787*1092MM (31*43''), that is, the width of the paper is 787mm, the length is 1092 mm, the cardboard texture is parallel to 1092MM; the generous 889*1194MM (35*47'') cardboard texture is parallel to 1194MM parallel. other special sizes can be customized.

Reel: 787/889 reel (large stock) and other special sizes can be customized (from 5 tons).

Packaging: wooden pallet + corner protector + stretch film, to ensure that the goods are packaged firmly to avoid damage during transportation.

delivery time

Regular size: 787*1092MM, 889*1194MM are basically in stock. The general delivery time for processing and mounting is 3-5 days, and the customized special specification is about 7-15 days

Features: The paper surface is fine, smooth and moderate, with good stiffness, straightness, sufficient thickness, toughness and not easy to deform.

Due to the special process and strict technical index control, all products have the characteristics of light weight, good stiffness, and not easy to deform. Especially in the microwave drying process, a sterilization process is also completed, so it is more and more popular in the food packaging industry. The green ignorance. The surface of the product is smooth and delicate, and the stiffness is good.

1. Quantitative

It refers to the weight per unit area of paper, expressed in g/m2, that is, the gram weight of one square meter of paper. The quantitative level of the paper determines the physical properties of the paper, such as tensile strength, tear, tightness, stiffness and thickness. Therefore, according to the characteristics of the equipment, arranging the quantitative printing parts corresponding to its performance for production can better reduce the consumption and improve the product quality and the efficiency of the equipment.

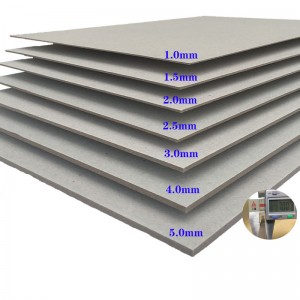

2. Thickness

It is the thickness of the paper, and the unit of measurement is usually expressed in ㎜. Thickness is closely related to quantitative and tightness. Generally speaking, the larger the thickness of the paper, the correspondingly high quantitative, but the relationship between the two is not absolute. Some papers are thin, but their basis weight is equal to or more than that of thicker ones. This shows the tightness of the fiber structure of the paper, which determines the basis weight and thickness of the paper. From the point of view of the use effect, it is very important that the thickness of the paper is uniform. Otherwise, it will affect the automatic paper feed, gluing evenness, etc.

3. Tightness

It refers to the weight of paper per cubic centimeter, in g/cm3. The tightness of the paper is calculated from the basis weight and thickness according to the following formula: D=G/d*1000, where: G indicates the basis weight of the paper; g is the paper thickness of.

The tightness is a measure of the density of the paper structure. If the tightness is too large, the paper will be easily brittle, the opacity and water absorption will be significantly reduced, and it will not be easy to dry.

It is also easy to calculate the cardboard thickness according to the above formula. Its formula is: d = G/D.

Example: Find the thickness of 500g/m2 double gray cardboard (its tightness tab is 0.625g/cm3, which is also our common indicator). 500g/m2÷0.625g/cm3=0.0008m=0.8mm

The unit conversion of m2 and cm3 mentioned in the previous step should be kept in mind, otherwise it is easy to cause misunderstandings. The method is: cm3/m2=(1*0.000001)m, converted into mm is our actual thickness.

4. Stiffness

It is the performance of the paper against the indentation of another object, and it is also the roughness of the fibrous tissue of the paper.

5. Smoothness

It refers to the degree of unevenness on the surface of the paper, expressed in seconds, which is measurable. The detection principle is: under a certain degree of vacuum and pressure, the time it takes for the air of a certain solvent to pass through the gap between the surface of the glass plate and the surface of the sample. The smoother the paper, the slower the air will pass, and the faster the air will pass.

6. Scaling rate

It refers to the dimensional variation of paper after moisture absorption or water loss. The softer the fiber structure of the paper and the lower the tightness, the higher the stretch rate of the paper; on the contrary, the lower the stretch rate.

7. Moisture content

Moisture content in cardboard. Generally speaking standard. The moisture content of double gray cardboard is 8-12%.

8. Vertical and horizontal

It refers to the direction in which the fibrous tissue of the paper is arranged. In the papermaking process, the direction of the fibers along the running direction of the paper machine is the longitudinal direction of the paper. It can be identified by the sharp angle presented by the web marks. Vertical to the vertical direction is the horizontal direction, the deformation value of the vertical paper pattern is small, and the amount of expansion and contraction during the use of the horizontal paper pattern is large.

9. Air permeability

In general, the thinner and less tight the paper, the more breathable it is. The unit of air permeability is ml/mim or s/100ml (second/100ml), which means the amount of air that passes through the paper in 1 minute or the time it takes to pass 100ml of air.

10. Front and back

During papermaking, the pulp adheres to the steel mesh and is characterized by filtering and dewatering. In this way, if the side of the net is lost due to the loss of fine fibers and fillers with water, net marks are left, and the paper surface is thicker. On the other hand, it is fine without relying on the net. Smooth, so that the paper forms a difference between the front and back. Although it has been dried and calendered in production, there are still differences in the front and back.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed